Frequently Asked Questions

Welcome to our Frequently Asked Questions or F.A.Q. page! Here, you’ll find answers to common questions about trailer parts, maintenance tips, axle compatibility, troubleshooting techniques, and more. Whether you’re new to trailer upkeep or just need a quick clarification, our FAQs are designed to help you find reliable information fast. If you still have questions, don’t hesitate to reach out—our team is here to help!

Hydraulic Brake Lines

How to bleed the brake lines when installing hydraulic brakes?

- Secure the brake to the backing plate on the axle.

- Put your hub back onto the spindle.

- Tighten the castle nut, install the cotter pin, and put the dust cap back on.

- Attach the brake line to the back of the brake assembly.

- (It is best to do this with two people) Open the bleeder, apply pressure to the tongue of the trailer, and then close the bleeder.

- You should have all of the air out of the line, leaving only brake fluid.

Wheel Installation F.A.Q.

How Should I Torque the Wheels?

Using a star pattern in the correct lug nut tightening sequence. See image below.

We get questions about torque often. To best prevent your wheels from coming loose, it’s important to install the wheel correctly by tightening the bolts in the correct lug nut tightening sequence. Always follow the proper procedures and use the recommended torque specifications when installing your wheels. Check out our YouTube tutorial for more information here!

Should I Use a Lubricant?

No. Keep it Dry. Never use lubricants. For proper torque wheel nuts, studs and mounting surfaces should be clean and dry.

What is my Lug Nut Tightening Sequence?

This is based on your bolt Pattern. See Below.

What is the Correct Lug Nut Tightening Sequence?

Lug Nut Tightening Steps:

- Hand tighten all lug nuts using a star pattern.

- Next, tighten all lug nuts to approximately 1/2 specification using the same star pattern.

- Tighten all lug nuts to full specification using the star pattern.

- Check torque after the first trip or 50 miles, whichever comes first.

Note: If the wheel is not a 5-Bolt wheel, then use the proper tightening pattern listed in the image above.

Note: Keep it Dry. Never use lubricants or penetrating fluids, for proper torque wheel nuts, studs and mounting surfaces should be clean and dry.

When should I tighten the lug nuts?

- After installation. Check torque after the first trip or 50 miles, whichever comes first.

- Periodically. Check torque regularly when refueling.

- Rust Signs. If you spot rust on the wheel, this indicates a loose lug nut.

The twisting and turning of your trailer will cause more stress than a normal automotive wheel and the lug nuts can work themselves loose over time. Periodically check the torque and watch for red rust coming from between the lug nut and wheel which is a sign of them loosening up.

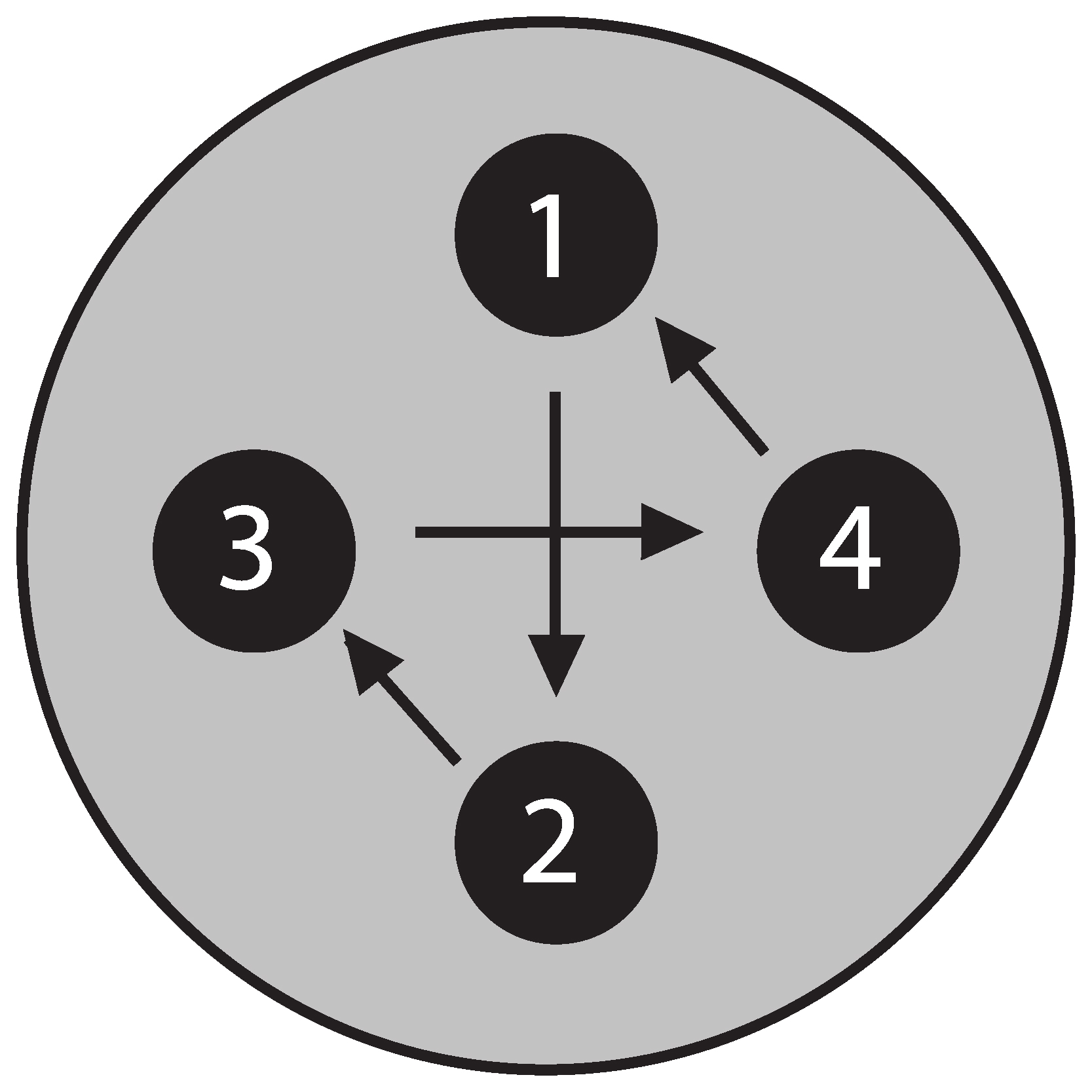

4 BOLT

Lug Nut Tightening Pattern

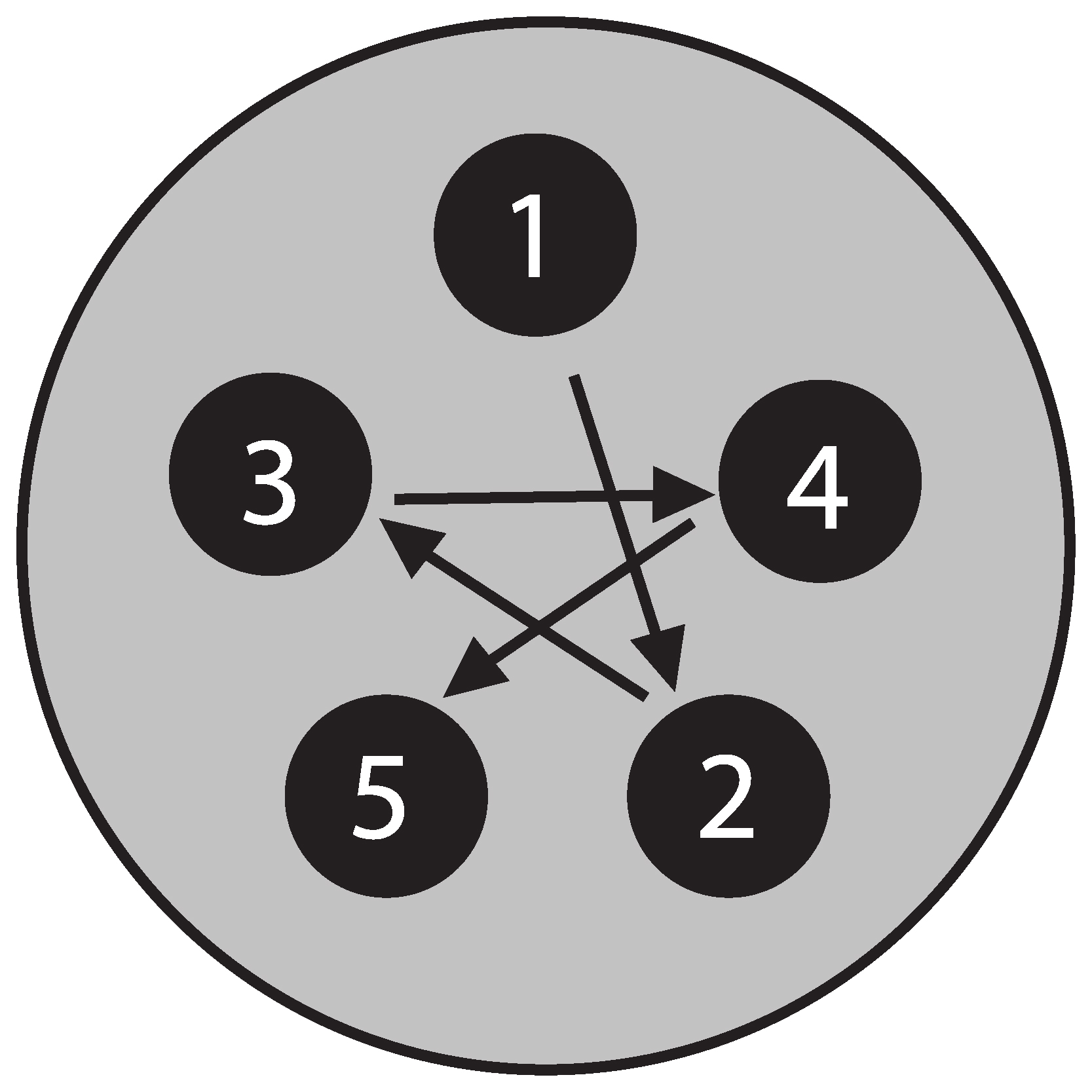

5 BOLT

Lug Nut Tightening Pattern

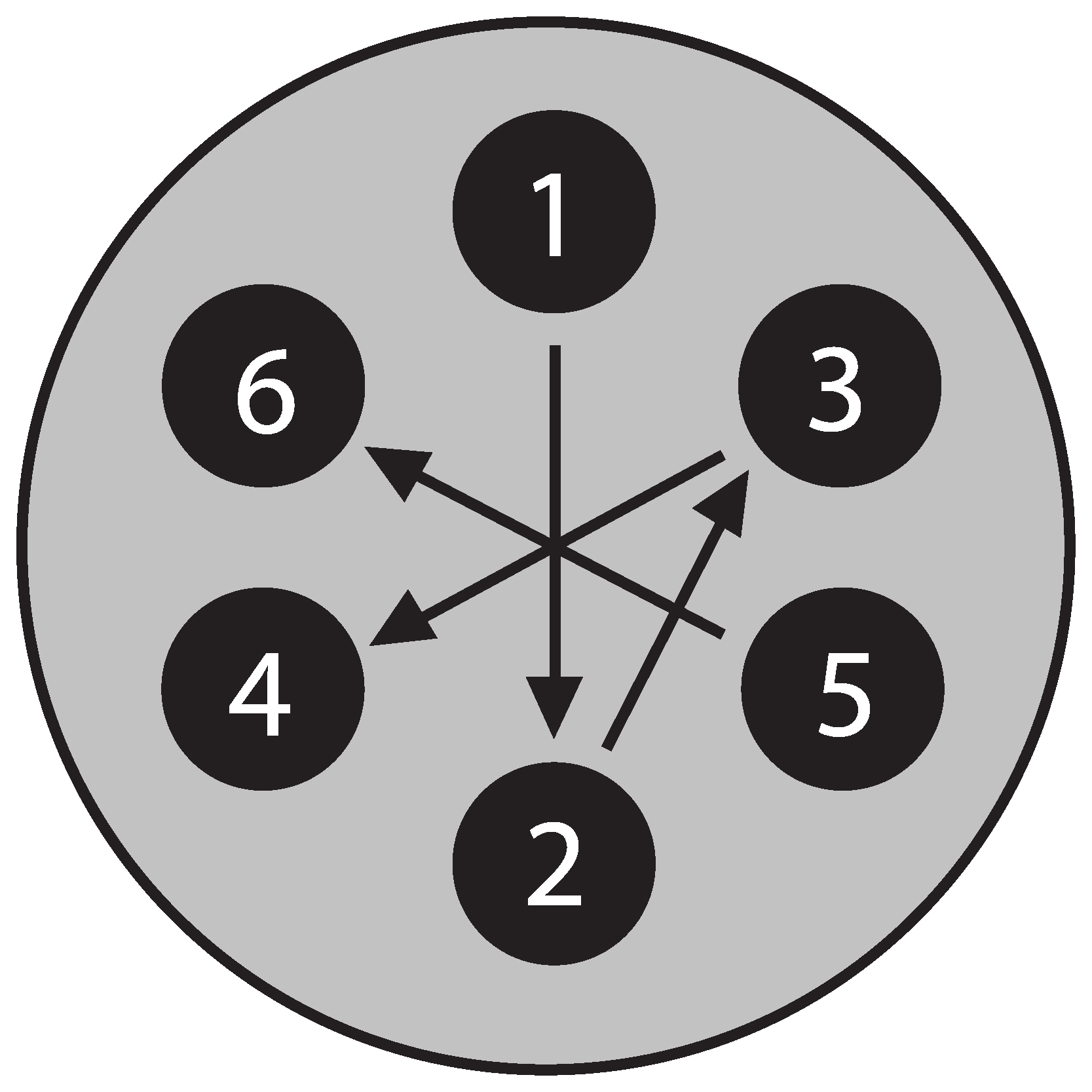

6 BOLT

Lug Nut Tightening Pattern

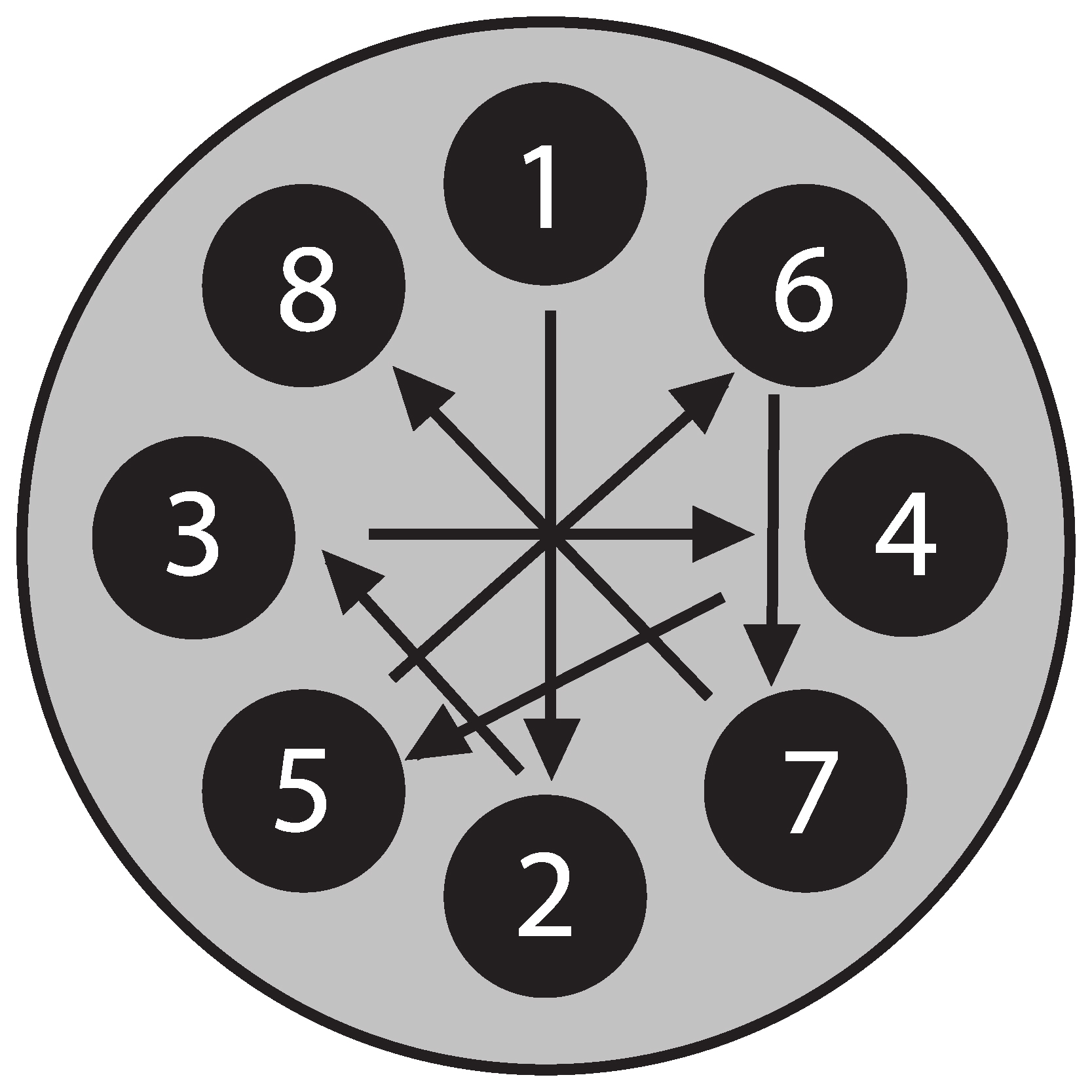

8 BOLT

Lug Nut Tightening Pattern

| Stud Size | Lug Nut Type | Torque Specifications | Wheel Size & Type | Wheel Material |

|---|---|---|---|---|

| ½” | Coned | 90-120 ft. -lb. | 15” | Steel |

| ½” | Coned | 90-120 ft. -lb. | 16” | Steel |

| 9/16” | Coned | 120-140 ft. -lb. | 16” | Steel |

| 5/8” | Coned with Wheel Clamp Ring | 190-210 ft. -lb. | 17.5” Single or 16” Dual | Steel |

| 5/8” | Flanged Nuts (Non-Rotating Flange) | 275-325 ft. -lb. | 17.5” Single or 16” Dual | Steel |

| 5/8” | Flanged Nuts (Rotating Flange) | 190-210 ft. -lb. | 17.5” Single or 16” Dual | Steel |

| ½” | Coned | 90-100 ft. -lb. | 15” | Aluminum |

| ½” | Coned | 90-100 ft. -lb. | 16” | Aluminum |

| 9/16” | Coned | 120-140 ft. -lb. | 16” | Aluminum | 9/16” | Coned | 130-150 ft. -lb. | 17.5” | Aluminum | 5/8” | Coned | 140-160 ft. -lb. | 17.5” | Aluminum | 5/8” | Flanged Nuts (Rotating Flange) | 150 ft. -lb. | 16” | Aluminum |

Can Axle Damage be Repaired?

Repairing axle damage depends largely on the type and extent of the issue. In many cases, certain axle components, like bearings, hubs, brakes, or springs, can be replaced individually without the need for an entirely new axle. Bearings, for instance, are designed to wear out over time and are relatively straightforward to replace, while hubs and brakes can also be swapped if they’re worn or damaged. Replacing these components can restore axle function and keep your trailer operating safely.

However, when there is significant damage to the axle itself, such as a break in the axle tube, a bend from impact, or stripped threads on the spindle, replacement is typically the best option. A break in the axle tube compromises its strength and safety, while a bend can cause alignment issues that lead to uneven tire wear, poor handling, and additional strain on other components. Stripped spindle threads are another serious issue, as they can make it difficult or impossible to secure the wheel properly.

In some cases, when the axle’s camber (the slight upward curve that helps with load distribution) or alignment is slightly off, a skilled technician may be able to carefully bend the axle back to its correct position. This process requires precise measurements and specialized equipment to ensure the axle is realigned safely. However, more often than not, the damage that causes alignment or camber issues is too extensive to repair effectively, and attempting to do so can lead to further complications down the road.

For the best results, if your axle shows signs of significant damage or misalignment, consider replacing it to ensure the safety, performance, and longevity of your trailer. If you feel yours may need to be replaced, you can shop our large inventory of both spring and torsion axles here!

What Happens When a Trailer Axle is Out of Alignment?

When a trailer axle is out of alignment, it can lead to a range of issues that affect both safety and performance. One of the most noticeable effects is uneven tire wear, as misalignment causes the tires to drag or scuff along the road rather than rolling smoothly. This irregular wear can shorten the life of your tires and even lead to blowouts if not addressed promptly. Misaligned axles also create increased rolling resistance, which can make towing more difficult and put added strain on the towing vehicle, potentially reducing fuel efficiency.

Additionally, an out-of-alignment axle impacts trailer handling, leading to swaying, tracking issues, or pulling to one side. These problems make the trailer harder to control, especially at higher speeds or when braking. If left uncorrected, axle misalignment can also cause stress on other components like the suspension, bearings, and hubs, which may lead to premature wear or even failure. To avoid these issues, it’s essential to inspect and correct any axle misalignment as soon as you notice unusual tire wear, handling problems, or tracking issues.

How Do I Identify My Axle?

To Identify your Trailer Axle, follow these steps:

1. Look for a Sticker

Start by checking the back of the axle tube for a sticker or tag. This label typically includes important information like axle brand, capacity, and serial number, making it the easiest way to identify your axle.

2. Measure the Hubface

If there’s no label, measure the distance between the centers of each hubface. The hubface is where the wheels mount to the axle. Measuring from one hubface to the other will give you the hubface length, which is critical for identification.

3. Measure the Spring Center

Next, measure the distance between the spring centers. The spring center is where the leaf springs attach to the axle. This measurement is essential to ensure the axle aligns properly with your trailer’s suspension setup.

4. Determine the Suspension Type

Examine the suspension setup to identify whether you have a spring or torsion axle. A spring axle will have visible leaf springs mounted to the axle, while a torsion axle uses a rubberized torsion system without leaf springs. Knowing this helps narrow down your axle type.

5. Measure the Tube Diameter

Finally, measure the axle tube diameter to estimate the axle’s weight capacity. Different diameters correspond to specific weight capacities:

Spring Axles:

- 1.75″ tube = ~1,000–2,000 lbs

- 2.375″ tube = ~3,500 lbs

- 3″ tube = ~5,200–7,000 lbs

- 3.5″ tube = ~8,000 lbs

Torsion Axles:

- 1.75″ tube = ~1,000–2,000 lbs

- 2.625″ tube = ~3,500 lbs

- 3″ tube = ~5,200–6,000 lbs

- 3.5″ tube = ~7,000 lbs

- 3.875″ tube = ~8,000 lbs

These measurements and characteristics will help you determine the axle type, capacity, and specifications needed for any replacements or upgrades.

What types of trailer axles do you sell?

We sell a wide variety of axles, including torsion, straight, drop axles.

Do you offer custom trailer axle solutions?

Yes, we can manufacturer a custom trailer axle for your needs.

How do I know which axle is right for my trailer?

Check your trailer’s weight capacity, size, and usage needs. Feel free to contact us for guidance.

What brands of axles do you carry?

We sell Duratek axles that are assembled here in the United States. 5-year warranty on spring axles. 10-year warranty on torsion axles.

Are your axles compatible with all types of trailers?

Yes, we offer axles for utility trailers, boat trailers, enclosed trailers, and more.

Do your axles come with hubs, bearings, and brakes?

You have the option to order just the axle beam or complete with pre-assembled components ready to install.

What are the weight capacities of your axles?

Our axles support a range from 2,000 lbs to over 10,000 lbs. Check individual product specs for details.

Do you sell replacement axles for RVs or campers?

Yes, we offer replacement axles and parts for RVs, campers, and other specialty trailers.

Can I upgrade my trailer’s axle to increase its load capacity?

In many cases, yes, but it may also require replacing other components like springs and tires.

Are your axles compatible with electric brakes?

Yes, we offer axles that are compatible with electric and hydraulic brake systems.

Do you ship trailer axles nationwide?

Yes, we ship across the U.S. and aim to deliver quickly and affordably.

How long does it take to receive my order?

Most orders ship within 2-3 business days. Delivery times vary based on your location.

Do your axles come with a warranty?

Yes, our axles come with 10-year warranty on torsion axles. There is 5 year warranty on spring axles.

What should I do if my axle arrives damaged?

Contact us immediately so we can resolve the issue and arrange a replacement if necessary.

Do you offer installation services?

We do not offer installation services. We have repair shops that we recommend for installation.

How often should I maintain my trailer axle?

Inspect your axle and bearings every 12,000 miles or annually for optimal performance.

What are signs that my axle needs to be replaced?

Look for wear like bent spindles, unusual tire wear, or difficulty towing.

Can I replace a single axle on a tandem-axle trailer?

Yes, but it’s critical to ensure the new axle matches the existing one in size and capacity.

Why should I buy from Blue Swift Axles?

We prioritize quality, offer competitive pricing, and provide expert customer support to ensure you get the best axle for your needs.

How can I contact customer support?

You can reach us via phone, email, or our website’s contact form.