5,200 lbs. Torsion Trailer Axle

$1,065.00

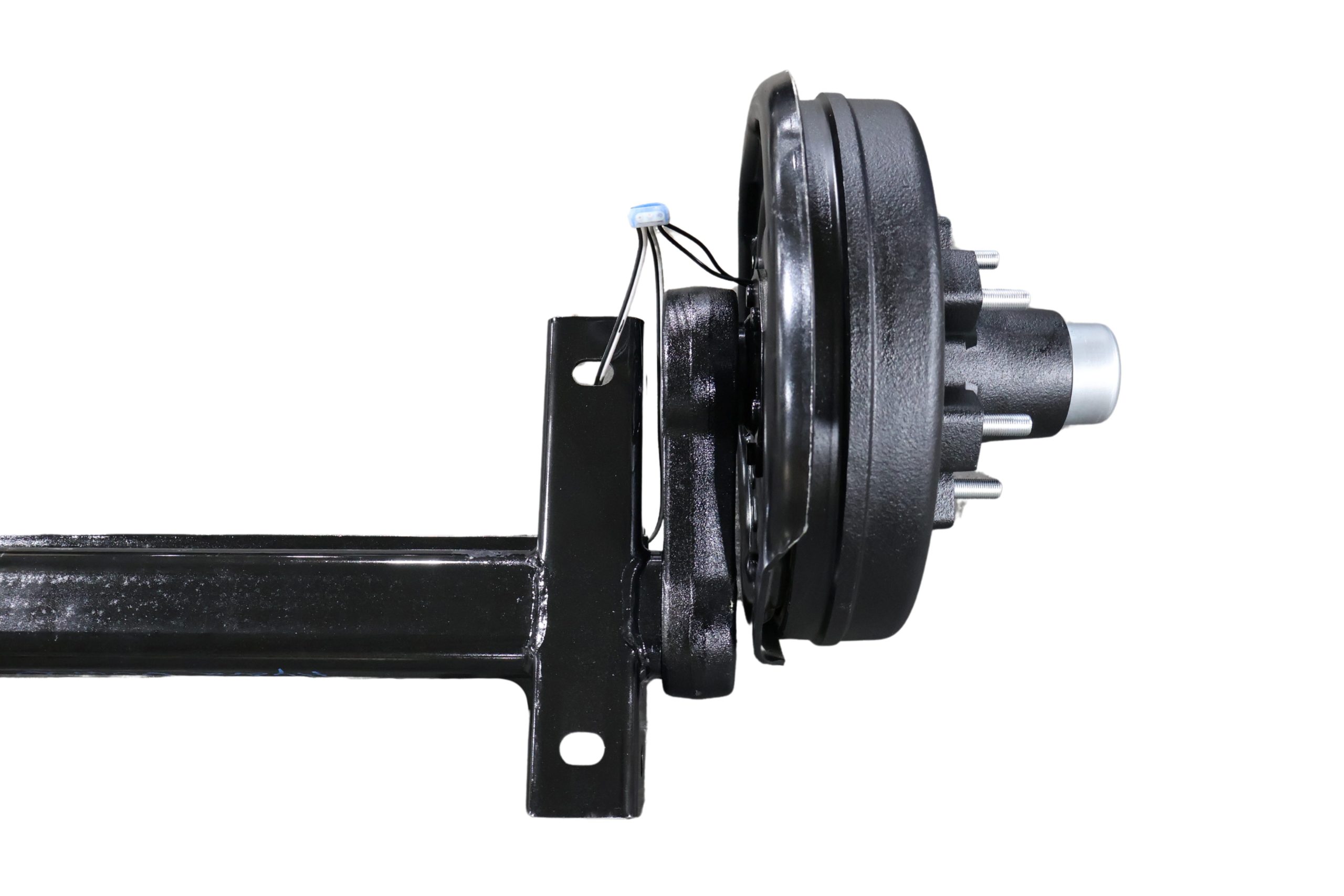

This Torsion Trailer Axle has a 5,200 lbs capacity. Custom built to customer specifications. Prices start at beam only.

In stock

Blueswift's 5200 lb. Torsion Trailer Axles are heavy-duty performers ideal for transportation companies. The durability of Torsion Axles makes them a top choice for companies seeking reduced maintenance costs. Torsion Axles are ideal for a smooth ride thanks to their independent wheel suspension.

Usage

- Highway Travel

- Heavy Duty Loads

Installation

Torsion Trailer Axles are welded or bolted directly to the frame of your trailer. This provides added support and stability for travel, ideal for excessive highway miles.

Maintenance and Repair:

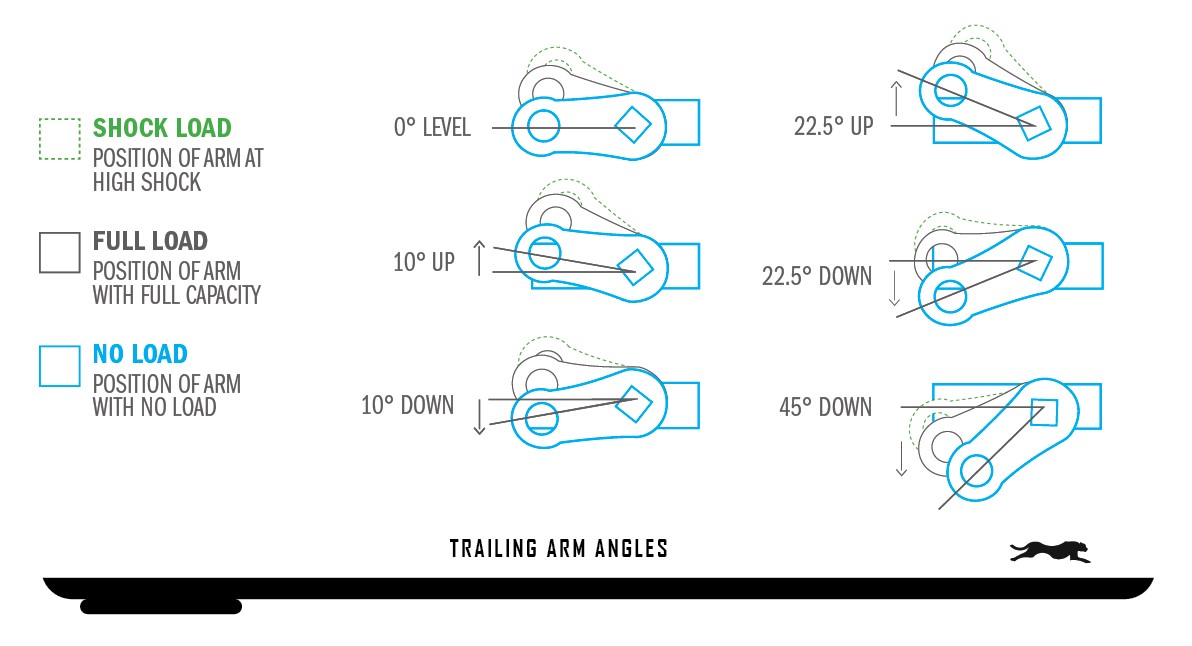

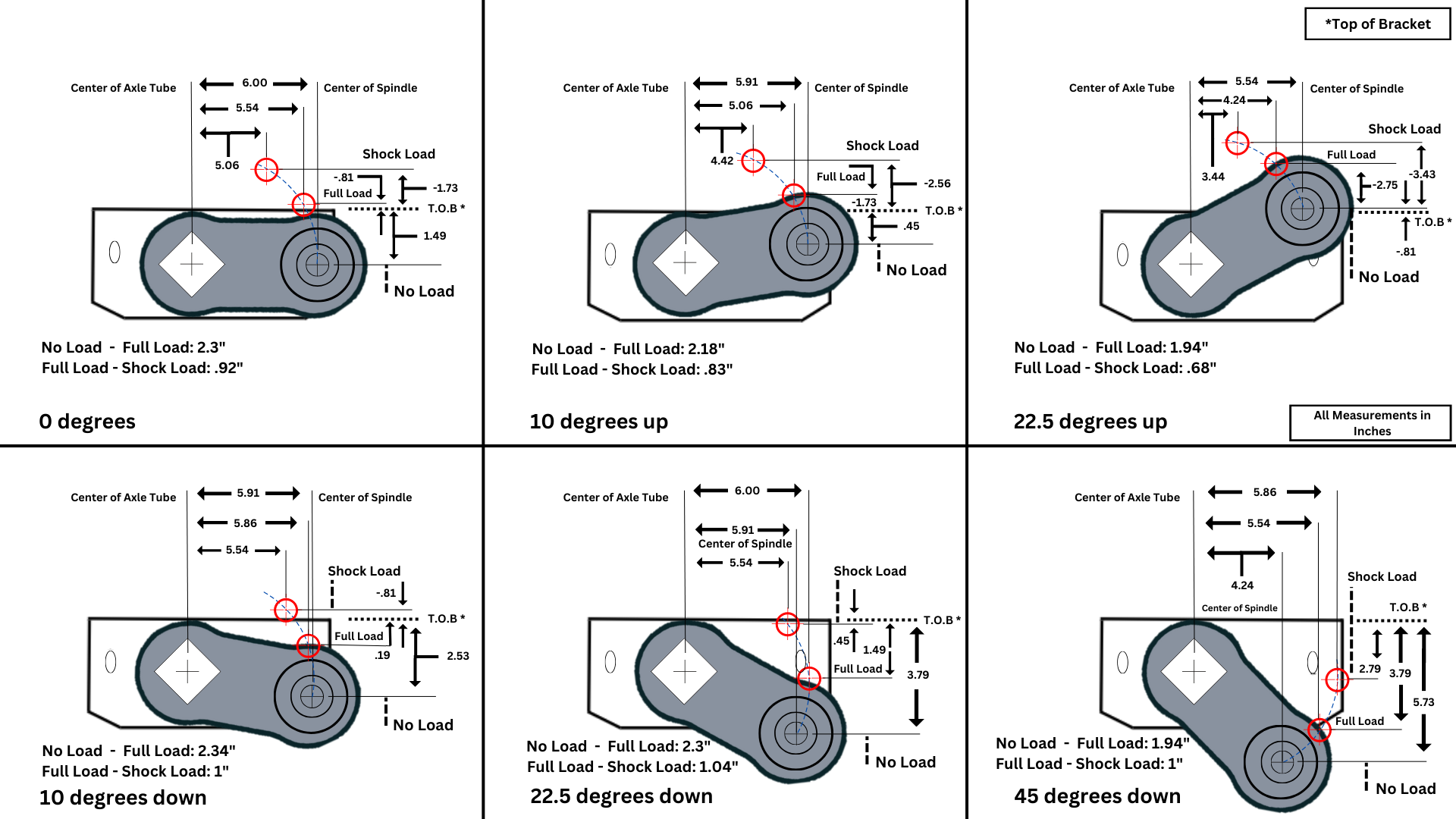

Maintenance in regards to Torsion Trailer Axles involves regularly inspecting the arms ensuring they still remain at their original degree and that the axle beam and mounting hardware are free from rust and damage. Repair typically requires replacing the entire axle assembly if the rubber torsion elements fail, as they are integrated and not serviceable individually.

Construction:

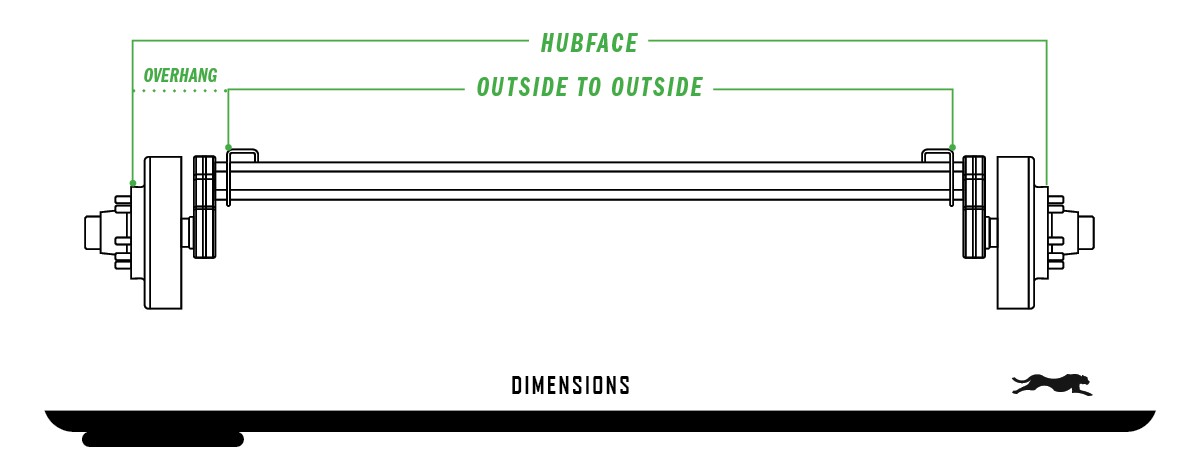

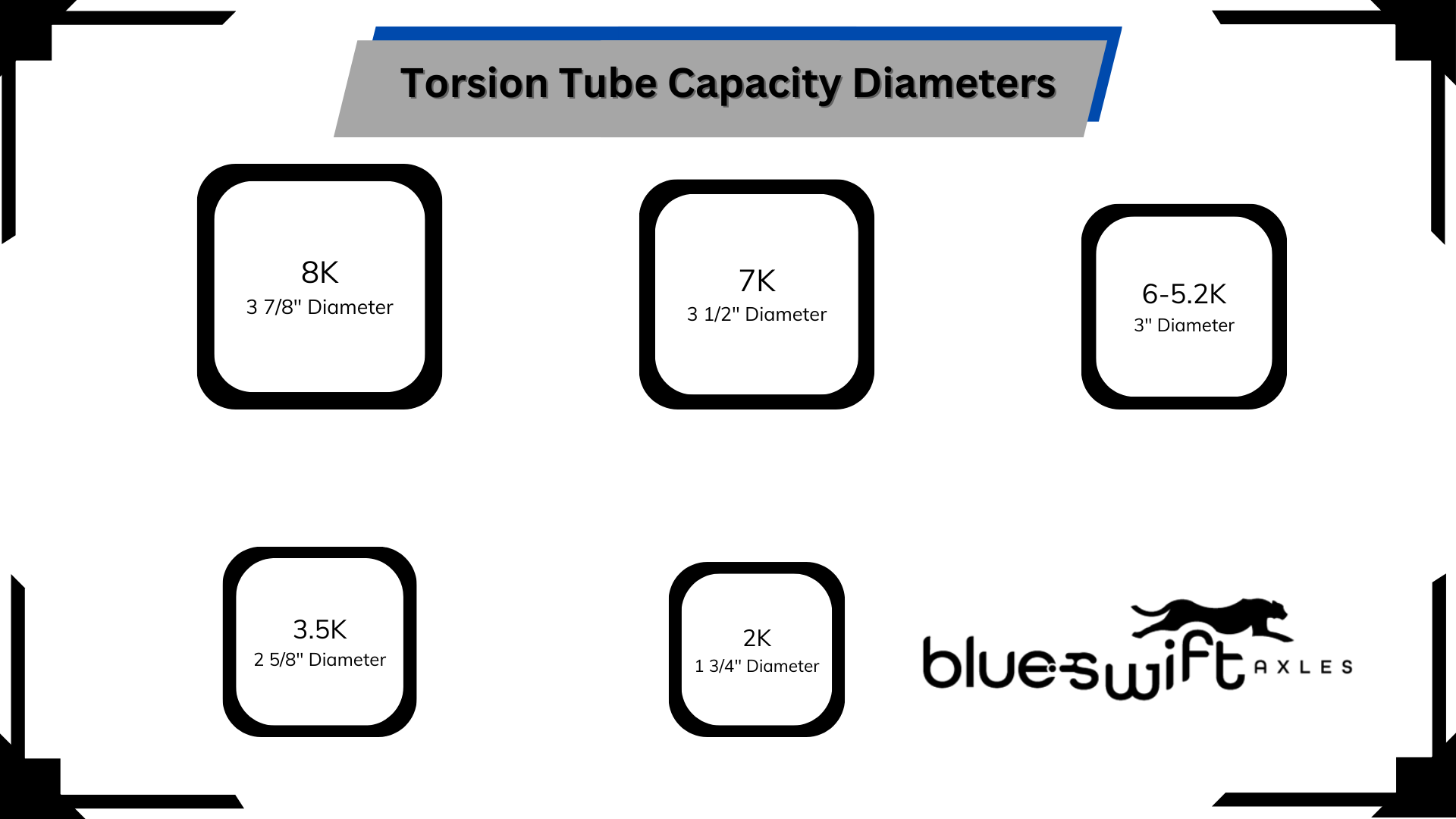

Torsion trailer axles are built with a rectangular beam that houses rubber cords, which provide suspension by compressing and twisting within the axle tube. The wheel spindles are attached to the ends of this beam, allowing for independent wheel movement and smoother ride quality. If you are switching from a Spring Axle to a Torsion Axle there are extra measurements that our team can assist you with at info@BlueSwiftAxles.com.

Additional information

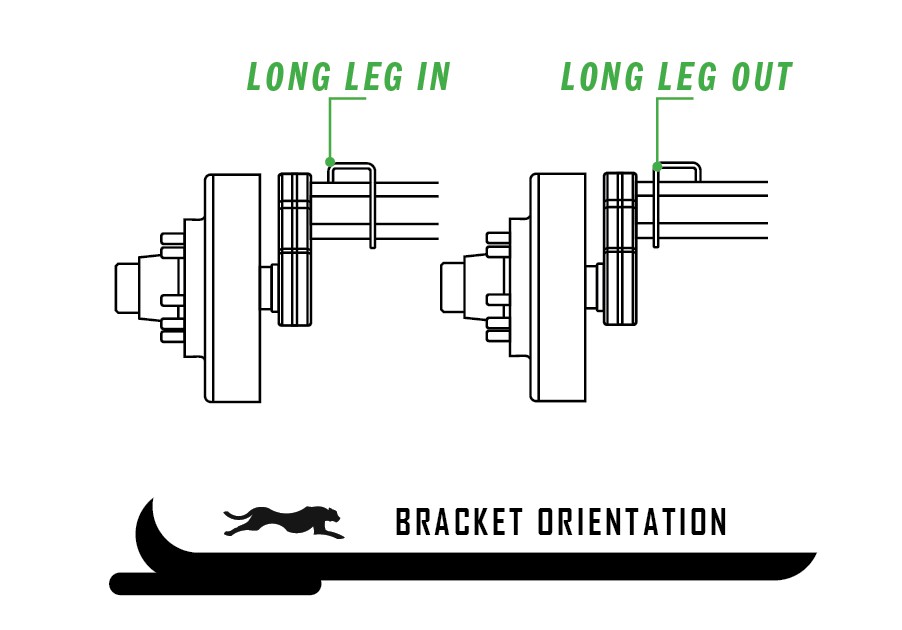

| Bracket Orientation | Long Leg In, Long Leg Out |

|---|

2 reviews for 5,200 lbs. Torsion Trailer Axle

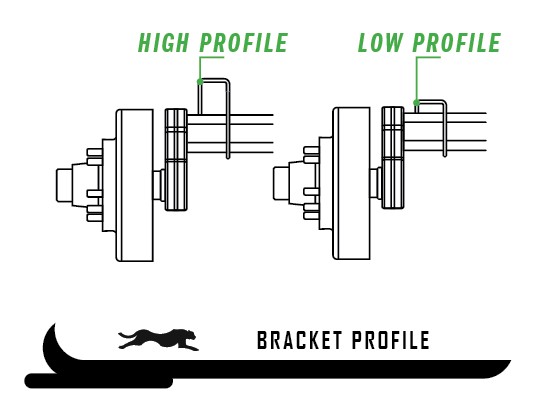

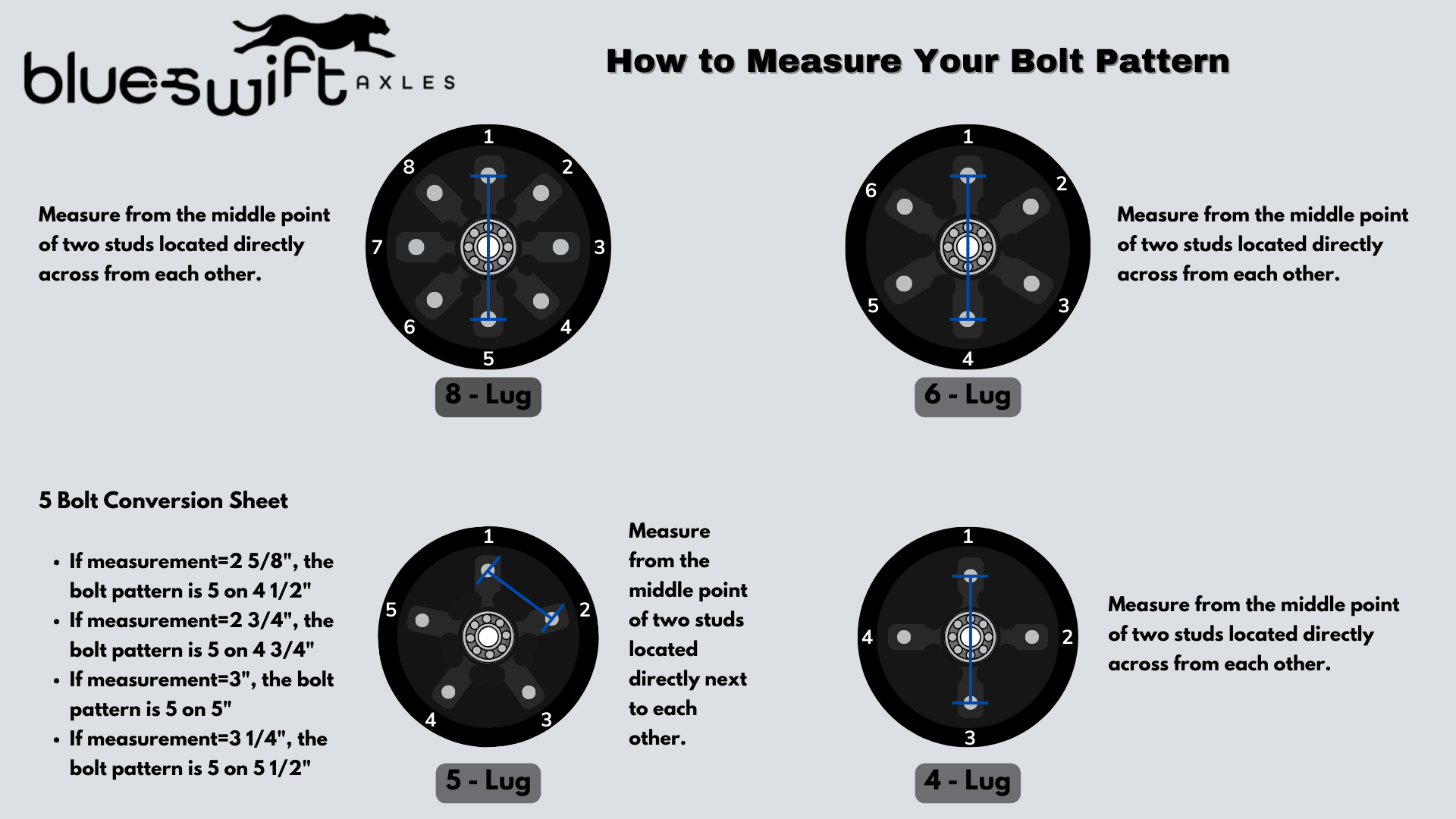

How To Identify Your Torsion Axle Brackets

Not sure which torsion axle brackets your trailer has? Identifying the correct bracket type and placement is essential for ensuring a proper fit and safe towing. In this video, I’ll walk you through everything you need to know to correctly identify your torsion axle brackets.

What You’ll Learn in This Video:

- Bracket Profile: How to determine if your axle uses low-profile or high-profile brackets and what that means for your trailer’s ride height.

- Bracket Orientation: Understanding whether your setup has long leg in or long leg out and why it matters for axle positioning.

- Measuring Bracket Spacing: Learn how to accurately measure the distance between brackets to ensure a perfect fit.

Bill Kiefel (verified owner) –

Daylon at Blueswift went above and beyond to help me. I emailed the company on a Sunday with a few questions and received a call the next day. Daylon and I discussed all the options so I got the perfect axle for my trailer. The axle fit perfectly. I was also impressed by the turnaround time. I received the axle in less than 2 weeks and the shipping was free.

Jeff Riebe –

A torsion axle went bad on our camper just as we arrived in Copper Harbor, MI. That is 7 hours from our home and we needed to get the camper out of that area within a couple weeks because winter sets in early there and they get up to 250″ of snow per year so we couldn’t leave our camper there for any length of time. The camper had Dexter axles so we contacted Dexter for new ones as well as sending them all the original info from the originals; when we spoke to them of our urgent situation they said, “we get a hundred of these calls everyday” it took them a week to get me a price and the expected delivery was up to 4 weeks after we accepted the proposal. I found Blueswift on the internet reached out to them late Sunday evening, they called me by phone Monday morning, gave me a price while on the phone, we paid them an extra fee for “quick turn-around” and on Thursday morning at 10am I received a phone call from a trucking company that the axles would be delivered to the campsite in Copper Harbor by noon……My wife and I went to Copper harbor on Friday, installed the axles(they fit perfectly!!!!!!!!) and had our camper safely home before any of the feared weather started…………This is truly a wonderful experience!!!!!!