7000 lbs. Torsion Trailer Axles

$1,200.00

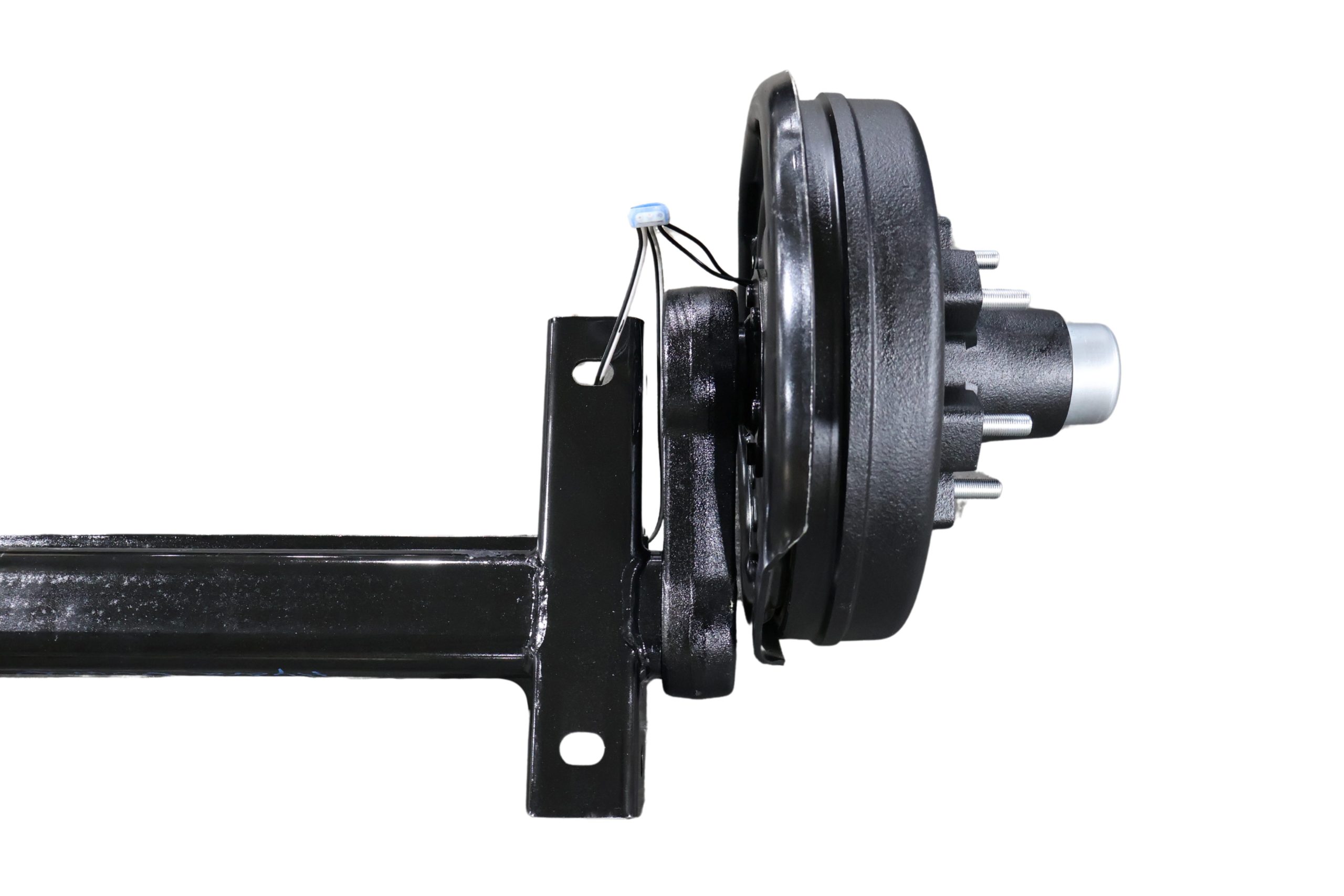

Torsion trailer axles are durable and reliable, making them a top choice for transportation companies and those looking to reduce maintenance costs. These axles offer a smooth ride during highway travel or when carrying heavy-duty loads. A Blueswift 7000 lbs. torsion axle is bolted or welded to your trailer frame, providing stability and support on the road.

In stock

Key Torsion Axle Features and Capabilities

Torsion axles deliver smooth rides and superior handling, making them a top-performing choice for many businesses. Features and capabilities include:

- Torsion bars: Torsion axles utilize torsion bars to absorb vibration and shock. These bars can flex and twist, creating a more stable and controlled ride.

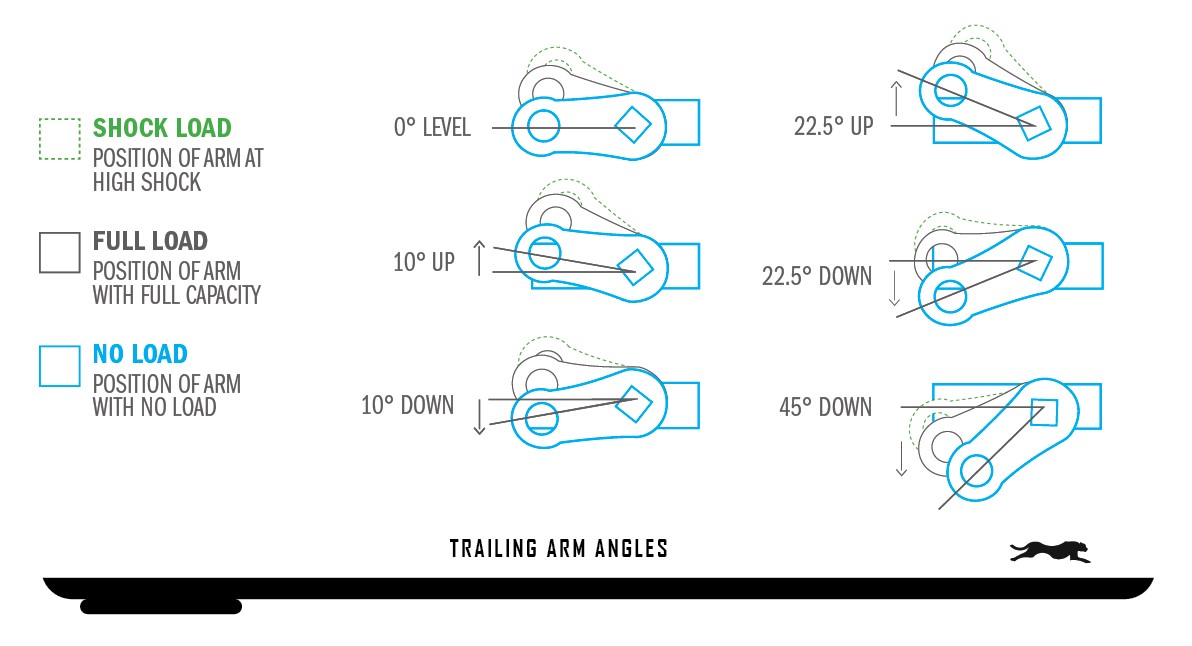

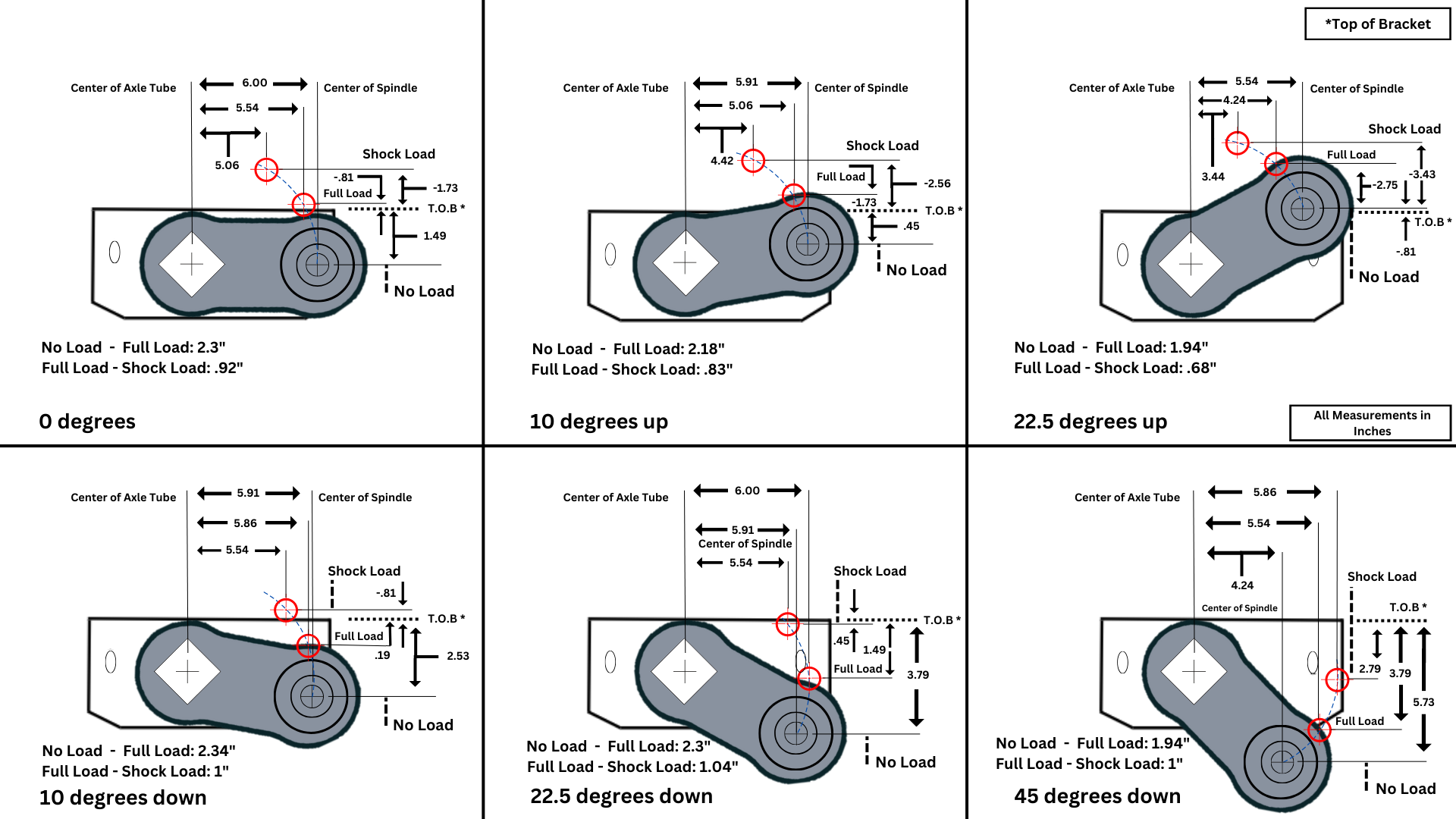

- Arm angles: These axles have arms that can sit at different angles to meet trailer needs. Arm angles will depend on a trailer's travel terrain, desired ride height and haul weight.

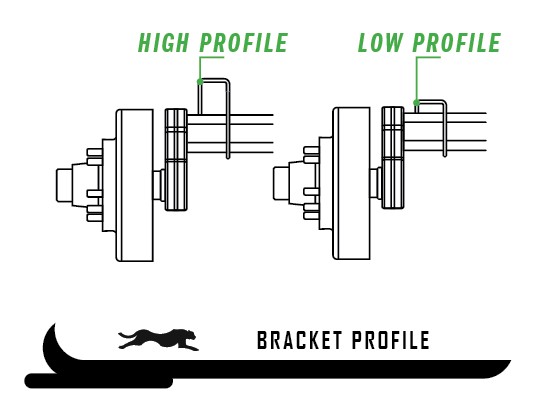

- Brackets: You can choose brackets with a high or low profile. Low-profile brackets essentially rest on the axle, while high-profile brackets increase the trailer's ride height by creating a 1-inch gap between the axle and frame.

- Improved handling: Torsion trailer axles reduce body roll and sway for better handling.

Comparing 7000 lbs. Torsion Axles to Spring Axles

Spring and torsion axles are two of the most common trailer axles. Selecting the right one ensures your trailer is road-ready. Here's how they compare:

- Ride comfort: Torsion trailer axles create a smoother ride than spring axles because the rubber torsion system can absorb vibration and shock more effectively than spring systems.

- Durability: Spring axles are more versatile, but torsion axles are more durable. Their rubber cords minimize friction and wear, and they have more resistance to corrosion. This increased durability is essential for those operating in unpredictable weather or in more challenging conditions.

- Cost: Due to the enhanced comfort, improved handling and increased durability, torsion axles are often more expensive than spring axles.

Maintaining and Replacing a 7000 Torsion Axle

Torsion axles require regular inspection. You must inspect the arms to ensure they maintain their original degree. You must also check the mounting hardware and axle beam for damage or rust. Typical repair involves replacing the axle assembly if you experience failure with the rubber torsion elements, as these integrated components cannot receive individual service. Torsion axles do not require greasing or lubrication. Only the hubs require their regular greasing and bearing repacks.

Choose Blueswift Axles for Trailer Axles

Blueswift Axles provides high-quality trailer products and components. Our products are suitable for towing businesses, hauling equipment or simply enjoying hobbies. Our team manufactures reliable 7000 lbs. torsion trailer axles and a full range of other trailer components. Our professionals deliver unmatched expertise with years of industry experience. We've earned the title of America's top trailer axles and parts provider thanks to our:

- Fast build times: Our state-of-the-art facilities, industry knowledge and advanced manufacturing techniques empower our team to build axles in as little as 48 hours.

- Custom builds: We custom-build trailer axles to support your unique needs and specifications.

- Superior service: Our customer service team ensures each customer feels we understand and value them, catering to their needs with a personal touch.

When you need trailer components, trust our team to help you find the right solution. Request a custom quote to get started, or call (515) 608-8040.

Additional information

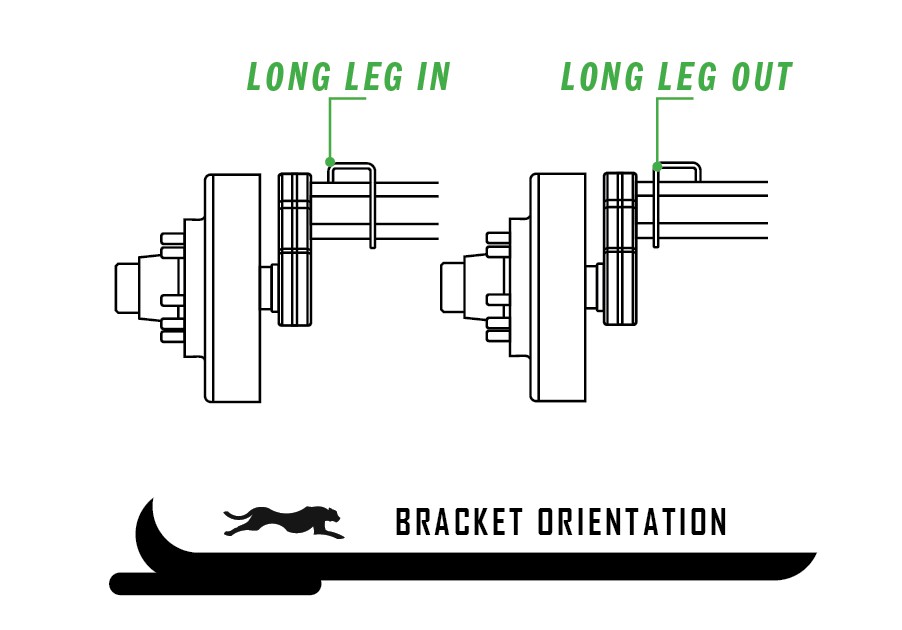

| Bracket Orientation | Long Leg In, Long Leg Out |

|---|

5 reviews for 7000 lbs. Torsion Trailer Axles

Steps To Identify Your Torsion Axle Brackets

Looking to replace or upgrade your torsion axle but unsure which brackets you have? Identifying the correct bracket type is crucial for proper fitment and safe towing. In this video, I’ll break down everything you need to know to correctly identify your torsion axle brackets.

What We’ll Cover:

- Bracket Profile: Learn how to determine if your brackets are low-profile or high-profile and how that affects your trailer’s ride height.

- Bracket Orientation: Find out if your axle uses the long leg in or long leg out configuration and why it’s important.

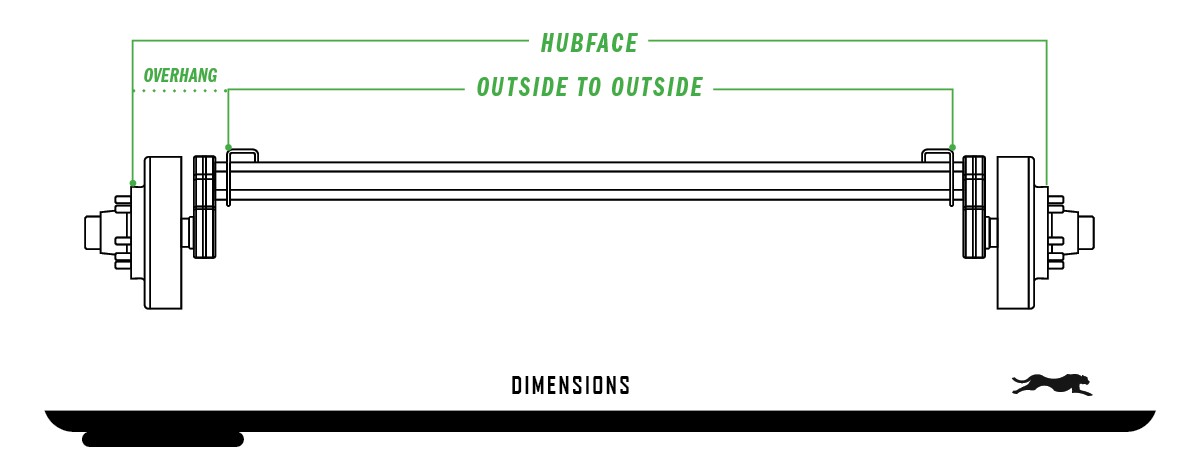

- Measuring Bracket Spacing: Get step-by-step instructions on how to measure the distance between brackets for a proper fit.

Mike Malone –

Needed two 7000lb axles quick. Blueswift delivered fast and measurement I gave them matched spot on. Could not be any happier. If you need axles and fast give Blueswift Axles a go, great team and finished product was excellent!

Robert Owen –

Great customer service, other places were 90 days out. I had these axles in 14 or so. No brainer moving forward I will order all my axles here.

Henry Brown (verified owner) –

Order made easy

Personal service, staff called back to make sure of measurements ,double checked everything, Really great and knowledgeable people.

Blake Monroe –

Awesome customer service!!

Called and ordered a torsion axle. Gave them my measurements and they had it made and shipped within 72 hours!

Awesome job Blueswift Axles!

Jonathan Ramer –

Ordered an axle from these guys and great service and product for great price!!! Thanks will be doing business with them again.