8000 lbs. Torsion Trailer Axle

$2,180.00

This Torsion Trailer Axle has an 8,000 lb capacity. Custom built to customer specifications. Prices start at beam only.

Blueswift's 8000 lb. Torsion Trailer Axles are heavy-duty performers ideal for transportation companies. The durability of Torsion Axles makes them a top choice for companies seeking reduced maintenance costs. Torsion Axles are ideal for a smooth ride thanks to their independent wheel suspension.

Usage

- Highway Travel

- Heavy Duty Loads

Installation

Torsion Trailer Axles are welded or bolted directly to the frame of your trailer. This provides added support and stability for travel, ideal for excessive highway miles.

Maintenance and Repair:

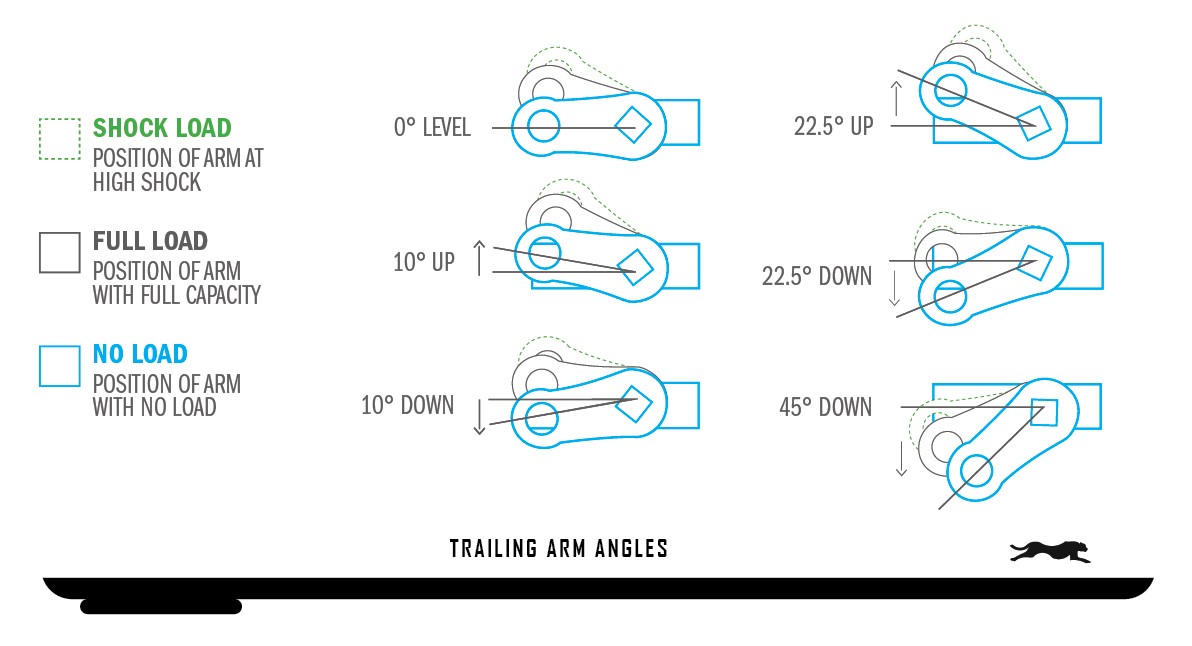

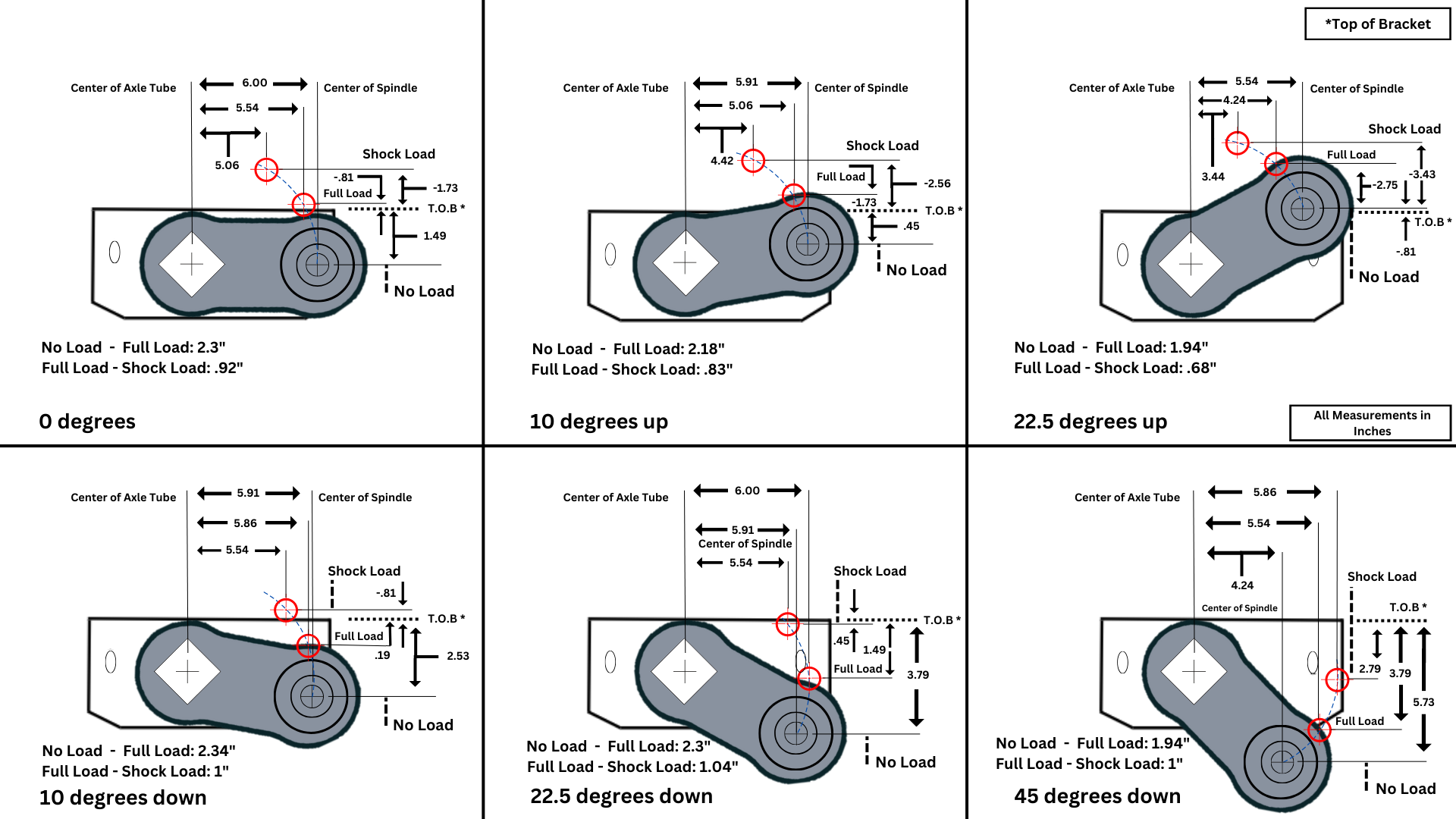

Maintenance in regards to Torsion Trailer Axles involves regularly inspecting the arms ensuring they still remain at their original degree and that the axle beam and mounting hardware are free from rust and damage. Repair typically requires replacing the entire axle assembly if the rubber torsion elements fail, as they are integrated and not serviceable individually.

Construction:

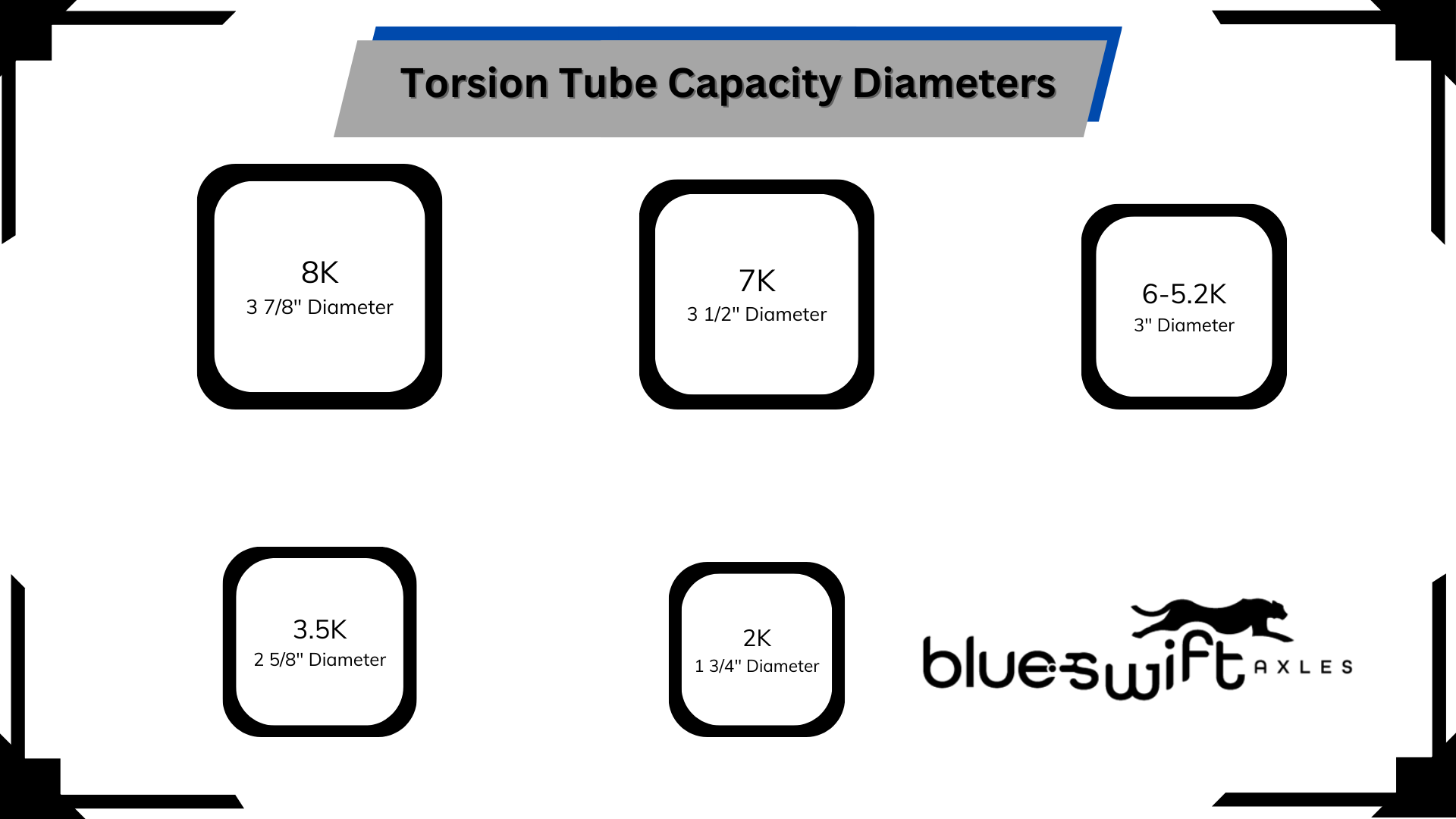

Torsion trailer axles are built with a rectangular beam that houses rubber cords, which provide suspension by compressing and twisting within the axle tube. The wheel spindles are attached to the ends of this beam, allowing for independent wheel movement and smoother ride quality. If you are switching from a Spring Axle to a Torsion Axle there are extra measurements that our team can assist you with at info@BlueSwiftAxles.com.

3 reviews for 8000 lbs. Torsion Trailer Axle

How To Identify Your Torsion Axle Brackets

Before replacing or adjusting your torsion axle, it’s important to know exactly what brackets your trailer has. In this video, I’ll walk you through how to identify key bracket details to ensure a perfect fit.

What You’ll Learn:

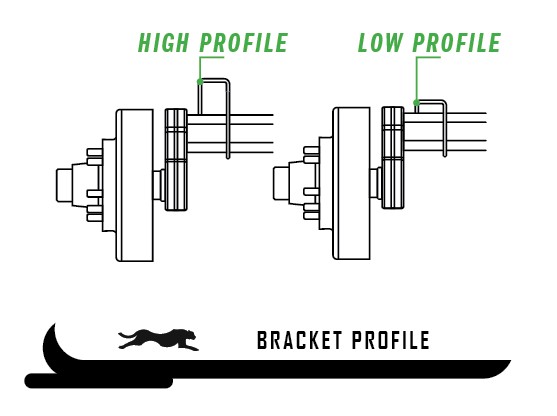

- Bracket Profile: How to determine if your brackets are low-profile or high-profile and how it affects ground clearance.

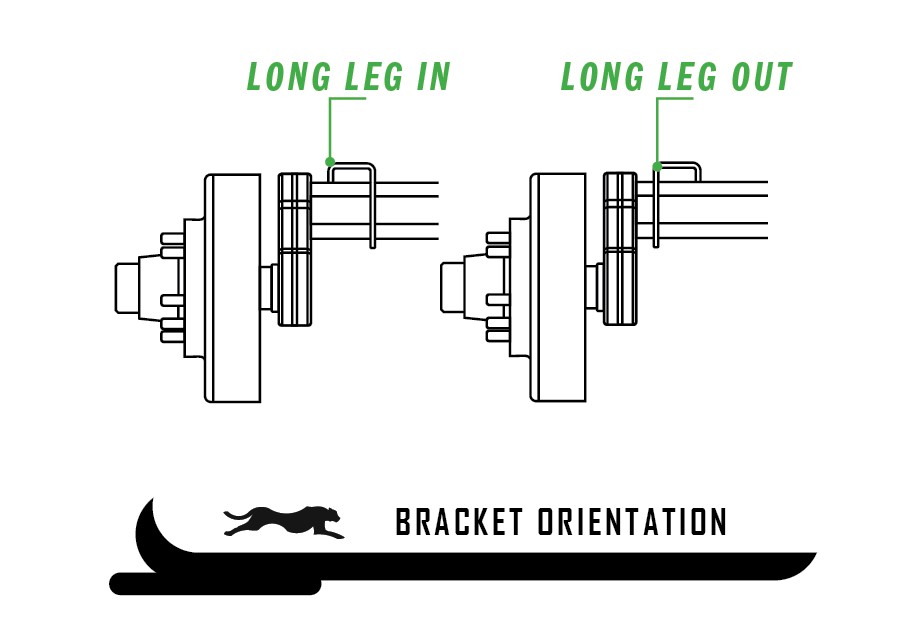

- Bracket Orientation: Understanding long leg in vs. long leg out and why it matters for axle positioning.

- Measuring Bracket Spacing: How to accurately measure the distance between brackets to match your trailer’s frame.

Riley Harvie –

The guys at BlueSwift were incredible to deal with! Great products, service & pricing. My trailer techs were so impressed with the 2 axles I had ordered they requested contact info for BlueSwift to order themselves. Thanks again for the awesome service & quality axles!!!

Corky Stout –

Quick friendly service and a good quality axle.

Steven Lewis (verified owner) –

I needed axles for a very specific suspension setup (Kelderman Manufacturing air/torsion system), which need no standard torsion axle mounting brackets. The other brands took weeks of fighting to get their engineers to understand what I was doing, after a single phone call and email with Daylon, they gladly built my axles and shipped them out in a week. Three times as fast as anyone else quoted me, And They built the axles exactly as I needed!

Great people to work with!